For the descendents of Richard Dearie and his son John Russell

J. A. Russell and Co. Ltd. News and other Sources 1959

The Straits Times, 26 January 1959, Page 8 THE following business done on the Singapore Share Market last week was reported by one firm of brokers for the period Jan. 17 to 23. INDUSTRIALS Malayan Cement $1.72, Malayan Collieries 55 cents and 53 cents

The Straits Times, 13 February 1959, Page 8 DEATH WARMINGTON. At Guy’s Hospital, London, on 11th February, Noel Makepeace Warmington, General Manager, Malayan Collieries Ltd., Batu Arang.

The Straits Times, 13 February 1959, Page 5 COLLIERIES CHIEF DIES KUALA LUMPUR, Thurs. The general manager of Malayan Collieries Ltd., Batu Arang, Mr. Noel Makepeace Warmington, died in Guy's Hospital, London, yesterday. He was 50. He fell ill just before Christmas and was sent to the Singapore General Hospital for treatment. Later he was advised to return to England. He leaves a wife, two sons and one daughter, all in England.

The Straits Times, 4 March 1959, Page 12 MALAYAN CEMENT, LIMITED (Incorporated in the Federation of Malaya) Notice is hereby given that the Ninth General Meeting of the Members of the Company will be held at the Registered Office of the Company, Hongkong and Shanghai Bank Building, Kuala Lumpur, on Thursday, 26th March, 1959, at 12.00 noon for the following purposes: - To receive and consider the Balance Sheet as at 30th November, 1958, and the reports of the Directors, General Managers and Auditors. To Declare a Dividend of 12 ½ %, less 30% Income Tax for the Year ended 30th November, 1958, payable on 26th March, 1959, in respect of the fully paid capital of the Company. To Determine Directors’ remuneration for the Year ended 30th November, 1958. To appoint auditors to hold office for the ensuing year. To transact any other business of an Annual General Meeting. Notice is also hereby given that the share register will be closed from Thursday, 12th March, 1959, to Wednesday, 25th March, 1959, both days inclusive, and the above dividend, if approved, will be paid to shareholders holding whose names appear in the Company’s Register of Members on 12th March, 1959. By Order of the Board J. A. RUSSELL & CO., LTD Secretaries, Kuala Lumpur, 4th March, 1959.

The Straits Times, 5 March 1959, Page 10 MALAYAN CEMENT, LIMITED It is regretted that due to an error the Rate of deduction of Income Tax from the proposed dividend stated in the Notice of the Ninth General Meeting in the Straits Times yesterday was incorrect. The Rate of Income Tax deductible should have read 40 per cent and not 30 per cent as stated. J. A. RUSSELL & CO., LTD Secretaries, Kuala Lumpur, 5th March, 1959.

The Straits Times, 6 March 1959, Page 10 FEDERATION DOUBLES FAVOURABLE TRADE BALANCE By Our Market Correspondent ……. Malayan Cement for the year to November 30 made a net profit before taxation of $1,858,141 or 14 per cent on a capital increased by a one for two rights issue. The net profit on the old capital was $2,698,637. Net current assets at balancing date, arrived at after deducting a $500,000 provision for future income tax and a debenture of $1,251,429 secured on the company’s assets in favour of Associated International Cement Ltd., amounted to $4,502,025 or 33.9 cents per share. The chairman, Mr. J. Drysdale, states that the accounts which cover the fifth year of the company’s operation, could be considered satisfactory although the profit earning climate was less favourable than in previous years. Above capacity During the year the works produced 109,664 tons of cement compared with a rated capacity of 100,000 tons. Good demand continued and all cement produced was sold. The present works expansion scheme increases the productive capacity from 100,000 tons to 220,000 tons of cement per year and as soon as the demand for cement justifies further expansion this will be made states Mr. Drysdale. The company has already announced a dividend of 12 ½ per cent is being paid on the increased capital. Business was unchanged yesterday at $1.65, and $1.64cd. (Extract)

The Straits Times, 23 March 1959, Page 13 NOTICE Malayan Cement Ltd. Rawang Works Expansion. Installation of the second kiln has now been completed, the new unit is operating most satisfactorily and Rawang Works is producing at the rate of 250.000 tons per annum. Expansion of sales has already commenced and tiger cement will soon be available in all parts of the Federation. The company anticipates meeting the entire cements requirements of the mainland.

The Straits Times, 26 March 1959, Page 17 SITUATIONS VACANT INSTRUMENT MECHANIC Malayan Cement Limited require an Instrument Mechanic for their Rawang Works. He must be thoroughly experienced and familiar with the repair and maintenance of pressure recorders, thermocouples, gas analysers, electronic recorders and pneumatic control systems. Good salary for the right man. Write P.O. Box 245, Kuala Lumpur.

The Straits Times, 13 April 1959, Page 10 New Serendah Rubber for the year to December 31 made a net profit of $222,955 equal to 43.6 per cent and including refund of planting cess amounting to $15,929.

The Straits Times, 8 May 1959, Page 10 In the industrial section there were buyers of Malayan Collieries up to 90 cents on the strength of rumours another capital return might be in the wind. Capitalisation. Previously 50 cents per share was returned.

The Straits Times, 25 May 1959, Page 10 MALAYAN COLLIERIES LTD., BATU ARANG Private Roads All roads within the property of Malayan Collieries Ltd., will be closed to all traffic for one day on Thursday the 28th May 1959. Permits for essential vehicular traffic on the above date may be obtained on application at the Personnel Office. G. W. WARNER GENERAL MANAGER

The Straits Times, 12 May 1959, Page 12 Twelve industrials drifted lower with Malayan Cement done down to $1.72. Malayan Collieries however, were maintained at 92 and 91 cents.

The Straits Times, 29 July 1959, Page 2 $2 MIL. CEMENT WORKS PLAN KUALA LUMPUR, Tues.— The Malayan Cement is planning alterations to its plant at a cost of $2 million which will increase production to 300,000 ton a year. The company's secretaries said today that the production of 12,838 tons of cement in April was achieved by using only one rotary kiln. “Our original kiln has now also been modified to produce more than the 108,000 tons it made last year”, a statement from the secretaries said. “This expansion and modernisation programme, carried out at a cost of $3 million has raised our productive capacity to its present 21,000 tons a month,” the statement continued. Consumption Although consumption of cement in the Federation totaled 245,000 tons last year it did not expect to exceed 22,000 tons this year. “Imports of foreign cements continue to pour into our potential market area. If the present rate is maintained our possible sales will be reduced by a further 60,000 tons this year. “Much of this foreign cement is entering the Federation at prices which clearly indicate dumping tactics by the exporting countries concerned.”

The Straits Times, 1 August 1959, Page 10 P.W.D. NOTICE The Rawang-Kuala Selangor road from the Malayan Cement Works, Rawang, to Batu Arang will be closed to traffic between 2 a.m. and 5 a.m. on Monday, 3rd August 1959 to enable heavy equipment to be transported. STATE ENGINEER SELANGOR

The Straits Times, 1 August 1959, Page 10 CEMENT OUTPUT Malayan Cement Ltd. report that monthly outputs from the Rawang Works for the second quarter of this year were as follows: April 12,838 tons, May 13, 619 tons, and June 16,589 tons.

The Straits Times, 2 August 1959, Page 4 $18.5 million Klang Gates will end floods in KL KUALA LUMPUR, Sat.— Floods and water shortages in Kuala Lumpur will be a thing of the past when the $18 ½ million Klang Gates' scheme near here, to be opened by the Sultan of Selangor on Monday, is in full operation. The scheme is described as the most ambitious launched by the Public Works Department in Malaya. It will ensure that: • NINETY days’ supply of 20 million gallons of water will be available per day to the Federal capital’s 350,000 people during droughts; • THE Klang River does not overflow its banks during rainy season, which in the past had been responsible for floods here. Predominating the scheme is a giant $4 ½ million dam. This dam will impound 3,000 million gallons of water from the source of the Klang River in a giant lake in its 750-acre site. It will absorb 30 million gallons of water a day, but will only release 16 million to flow into the Klang River, thus reducing the dangers of overflow. The dam was designed by the Bureau of Reclamation in Denver, Colorado, in the United States, in 1951, when the project was initiated. More than 1,600 tons of ice was used to chill the concrete mixture of millions of tons of Malayan cement used in the building. This had been recommended by the designers. Ice for concrete The ice was used to cool the concrete to ensure there was no shrinkage later thus preventing cracks. It was entirely constructed by local artisans and special plant purchases. The dam’s resident engineer, Mr. L. M. Williams told the Sunday Times in an interview today, that one of the unique features in the construction work was the absence of loss of life or limb. Mr. Williams said that it was unusual to have no accidents in projects like this. The Sunday Times learnt that the Public Works Department will soon call for tenders for the sale of $1 million worth of equipment purchased for this project. The Klang Gates’ scheme includes a modern purification plant at Bukit Nanas here, which at present has a capacity of 20 million gallons a day. This will be increased to 30 million a day soon. Considerable amounts of new pipelines have been laid for this project. The final stage will be the laying of new main pipes, which will carry twice the amount of water carried by the old lines.

The Straits Times, 4 August 1959, Page 6 The Foundation of Malaya’s Economy Malayan Cement Limited have recently supplied Cement for the Klang Gates Dam. Malayan Cement Limited can now supply the entire cement requirements of the Federation of Malaya. TIGER CEMENT An Advertisement of---------------------------- MALAYAN CEMENT LIMITED

The Straits Times, 31 August 1959, Page 18 Markets Steady counters were……Malayan Collieries at 99 ½ cents….. Easier were cements at $1.60

The Straits Times, 9 September 1959, Page 2 Sultan to open extension KUALA LUMPUR. Tues.— The Sultan of Selangor will open the new works extension of the Malayan Cement Limited at Rawang next Tuesday. The Minister of Finance, Mr. Tan Siew Sin, will speak.

The Straits Times, 13 September 1959, Page 4 CALL FOR FUNDS TO FIGHT TB KUALA LUMPUR, Sat. The Lady Templer Hospital here today made an urgent appeal for donations "no matter how small"— to carry on its fight against tuberculosis. The target is $500,000. The chairman of the Board of Governors, Sir John Drysdale, said in a circular that a donation of $5,000 would endow a bed in the hospital for one year. “Hundreds of people of all races have been cured in this hospital but there are thousands of others who are suffering from this killer disease. More and more patients are seeking admission. “More funds are required to meet the increasing cost of running the hospital, which also helps members of the public in taking X-ray films.” The letter added that only 17 beds had so far been endowed by business firms and Industrialists the need for funds was urgent. The Government gives a generous annual grant, nut there is still a shortage of income which could only be met by public donations.

The Straits Times, 15 September 1959, Page 9 MALAYAN CEMENT-STRAITS TIMES FEATURE $7.5 m BOOST FOR CEMENT by Saul Joshua. Factory can meet country’s needs. The Federation Government’s policy of industrial development to expand and diversify the economy of the country has encouraged Malayan cement Ltd., the only cement works in the country, to go ahead with its expansion and modernisation programme. Second kiln This expansion programme carried out at the cost of about $7,5000,000, has just been completed and today a simple ceremony to be performed by the Sultan of Selangor will mark the start of production of the second rotary kiln at the company’s factory in Rawang, Selangor. The new plant includes a second kiln, two grinding mills, extensions of existing buildings and a variety of ancillary equipment—one of them a dust collector fitted to the kilns to reduce the emission of dust from the factory chimney. Building, constructional engineering, road-making and bridging, air and sea port planning, water supplies, hydraulic power, electricity, irrigation schemes and canalisation all require cement. And with the increased demand for cement in Malaya, Malayan Cement Ltd., which produces the popular Tiger Brand Portland Cement, has initiated its extension programme to meet the new requirements. Production at the factory started in 1953 with an initial capital of $10,000,000. Now Malayan Cement has more than doubled its output from the original 100,000 tons a year to 220,000 tons. This means that Malayan Cement will be able to supply the entire cement needs of the Federation as the estimated consumption is about 250,000 tons a year. Its capacity. The Rawang factory, however, can be worked up to produce 300,000 tons annually although it has a rated capacity of nearly 230,000 tons. Malayan Cement cannot currently utilise their full capacity because: ALTHOUGH consumption of cement in the Federation totalled 245,000 tons last year, it is not expected to exceed 220,000 tons this year; and IMPORTS of foreign cements into their potential market area are pouring in and if the present rate is maintained their possible sales off take may be reduced by a further 60,000 tons this year. The company, however, hopes to capture the entire Malayan cement market with its extension programme. The company is giving active consideration to additional alterations costing a further $2,000,000 to increase its capacity to 25,000 tons a month or 300,000 tons a year within 12 months. Increased efficiency in the transportation system—one of the biggest problems in the cement trade—is among the company’s immediate plans. To make their system highly efficient, the company will add two bulk road wagons and more bulk rail wagons to its present transport fleet. As a result of this, cement will soon be available to customers in the Kuala Lumpur area in bulk, carried by special road transporters direct to job sites where it will be pumped into portable silos (storage tanks) ready for use. Advantages This method of delivery will benefit customers by a direct reduction in cost. Indirectly the advantages are: DETERIORATION of cement caused by rain and high humidity will cease; THE NECESSITY of erecting site storage for bagged cement will be obviated; SITE pilferage will be prevented; and SITE movement of cement will be eliminated, resulting in a reduction of handling and labour charges. The company also plans a new depot in North Malaya to increase the efficiency of its service to customers. New lorry loading arrangements at Rawang to facilitate and speed up the loading of customers’ lorries are also being planned. The company is currently investigating the potentiality of a combined rail and road service to enable them to offer bulk delivery to larger job sites throughout the Federation. By this method, cement will be carried in bulk rail wagons to the nearest station to the site, and then pumped into the bulk road transporters for delivery. The latest storage methods will also be introduced by the Company. (See page 12 col 5) New schemes for cheaper cement (From page One) Portable silos will be provided at work sites by the company on an easy payment basis. These improvements in transportation and storage are aimed at lowering the cost of cement to big customers. It is expected that the reduction will be about $5 a bulk ton once these methods are in full operation. The company believes that with “a lot of trade strategy” it may be able to make its cement available at a uniform price in all places in the Federation. One of the largest industrial undertakings in the Federation, Malayan Cement Ltd. is a member of the Blue Circle family, the largest cement organisation in the world. Fully tested. At the disposal of the organisation are modern research laboratories and testing plants. Chemists carry out tests at each stage of manufacture to ensure that production not only complies with the British standard specifications for Portland cement, but exceeds them by a generous margin. Consignments are sampled and tested, with a reserve sample put aside as a check against any possible complaint. The Blue Circle group has a worldwide network of cement factories—29 of them in Britain and 12 others in ten other countries. This makes it possible for Malayan Cement to call on the group’s long established experience for technical information, laboratory tests and engineering and administrative techniques. Part of the company’s present expansion programme is towards the welfare of its employees. Besides providing free housing, light and water and medical treatment, the company recently opened the Blue Circle Club to provide recreational facilities at Rawang. These include an excellent football pitch, two floodlit badminton courts and a floodlit tennis court. • Malayan Cement Ltd. have five major distributors whose names are household words throughout Malaya. They are: Boustead and Co Ltd.; Guthrie and Co Ltd.; Harper Gilfillan and Co. Ltd.; James Warren and Co Ltd.; and William Jacks and Co (M) Ltd. The fact that the Tiger cement is to be seen in godowns from Ador Star or Kota Bharu down to Johore Bahru any and every day, sight is lost of the immense amount of physical handling and work necessary to bring this about. The company’s current capital is subscribed by some 940 shareholders of whom 80 per cent reside in Malaya. Actual figures are 445 in the Federation, 300 in Singapore and 195 overseas. Despite trade setbacks, Malayan Cement made a profit of $2,723,000 last year. Picture Mr. J. Hamilton, works manager at Rawang.

Advert TIGER BRAND—MALAYAN CEMENT LIMITED—PORTLAND CEMENT Helping to build Malaya. With two kilns now in operation the company is fully capable of meeting the entire cement demands of the Federation of Malaya. MALAYAN CEMENT LIMITED, Kuala Lumpur WORKS—RAWANG, SELANGOR.

The Straits Times, 15 September 1959, Page 10 Advert Congratulations to MALAYAN CEMENT LTD on their continuing progress and expansion BOUSTEAD & CO., LTD. Singapore Penang Kuala Lumpur Ipoh Kota Bharu Malacca Kuala Trengganu Kuantan Advert Congratulations to Malayan Cement Limited on the opening of their New Works Extensions at Rawang. WING COMPANY 457, BATU ROAD, -K.L.- TEL: 85632 PILING SPECIALISTS and GENERAL CONTRACTORS We are pleased to have been associated with the building of the extensions and were responsible for the construction of the reinforced concrete piers, foundation works, etc. Advert EUCLID REAR-DUMPS for moving earth, rock, coal and ore Rear-Dump Euclids are built for long life in the heavy service of mine, quarry and construction work. Their rugged construction results in less down time for repairs and more work done day after day….low cost performance that has been proved on hundreds of operations all over the world. Picture The Model UD has a capacity of 9 metric tons…is powered by a diesel engine of 128 h.p……has 10-speed gear box….spring mounted drive axle. There is a size and type of Euclid to fit every job requirement…payload capacities from 20,000 to 80,000 lbs., 9-36 metric tons…128 to 500 total h.p….5 or 10 speed gear box or torque converter with semi-automatic transmission…top speeds up to 36 mph, 58 km/h. With Euclids on your work you have the advantage of performance-proved design resulting from over 25 years of leadership in building heavy earthmoving equipment. As your Euclid dealer, we have a large stock of factory parts and an experienced staff to help keep your equipment in first class operating condition. May we give you complete information on Euclid rear-dump haulers and show you why the give the best return on investment? Picture Model FD Euclids carry 13.5 and 16.3 metric tons…have engines of 154 to 220 h.p…5 speed transmission…hydraulic power steering…quarry body optional The FD units are as used by Malayan Cement Ltd., Rawang in their quarry and were supplied by the Euclid distributors HARPER, GILFILLAN & CO., LTD. Advert: Congratulations to MALAYAN CEMENT LIMITED on the Opening of the New Works Extensions at Rawang FROM HARPER, GILFALLEN & Co., Ltd. Distributors Throughout Malaya OF “TIGER” BRAND CEMENT Advert We Congratulate Malayan Cement Ltd. on the occasion of the opening of their SECOND KILN JAMES WARREN & Co., Limited. Distributors of "TIGER CEMENT" Throughout Malaya. Advert Hearty Congratulations TO Malayan Cement Ltd. On the occasion of the opening of their New Works Extensions at Rawang FROM KANG AH BAH 100-C, Bungsar Road, Kuala Lumpur. Contractors for Steel Fabrication, Pipes, Concrete Linings, Metal Spraying, Galvanising.

The Straits Times, 15 September 1959, Page 11 MEET... MR. K. M. JOSEPH, the works accountant. He is in charge of the general office and administration. Before joining Malayan Cement Ltd. in 1953, Mr. Joseph worked on rubber estates and tea plantations. He has a team of over 10 clerical and accounting staff. MR. P. E. WEBSTER, works engineer, is in charge of the entire machinery. Mr. Webster had been working with Associated Portland Cement Manufacturers Ltd., parent company of the Malayan Cement Ltd., before coming out to Malaya. MR. E. U. KIDAV, works chemist, is in charge of the well-equipped laboratory. Mr Kidav, 29, is one of the Asians who has benefitted under the company’s training programme enabling Asian staff to fill top posts at the factory. He joined the company when the factory opened as a laboratory assistant and was later sent to the parent company’s factory in Britain for six months training. He leads a team of four chemists and four laboratory hands. The team carries out a 24-hour vigil, testing the quality of the cement produced at the factory

(Photo and details of the cyclone dust collectors) DUST PROBLEM SOLVED The cement dust from the chimney has been a nightmare to the factory management from the start of production six years ago. The dust, scooped up from the kiln by the escaping chimney steam, had been settling over the entire factory surroundings reducing the landscape to an ugly mass of grey-coated vegetation and buildings. People living near the factory petitioned the State Government and suggested that the factory stop producing cement as it was the only way to stop the dust nuisance. The management has settled the problem but at a cost of $450,000. Two sets of cyclone dust collectors have been installed during the extension programme to deal with the dust problem. Each set will serve each of the two kilns. The cyclone seen in the foreground (four cone-shaped objects) serve the new rotary kiln. The cyclone dust collector for the old kiln can also be seen in the picture. The escaping steam from the kiln charged with cement dust is fed into the top of the dust collectors where a powerful draught fan works. The dust is collected and falls to the bottom of the cone and the steam is cleared to give dust free chimney flue. The dust collected in the cyclones is then fed back to the kilns and the process is continuously repeated.

THE MANUFACTURING STORY… The Coal and Shale from Batu Arang make your cement. The materials used for the manufacture of Portland cement may be limestone and shale as at Rawang or chalk and clay. At Rawang limestone is quarried by drilling and blasting and is loaded by electrically-driven shovels into dumper lorries for transport to the crushers which reduce the size to approximately one inch diameter—convenient for handling in the ball mill. The shale is dug at Batu Arang and brought, with the coal for firing the kiln, in railway trucks to the cement works. Large storage tanks Regulated quantities of crushed limestone and shale are taken from the raw materials store and fed continuously into the tubemill where the materials are ground with water by steel balls and emerge as a well-mixed “slurry.” The cement slurry is pumped to large storage tanks where it is kept agitated with compressed air. The slurry is tested frequently and adjustments made to ensure that the fineness, calcium carbonate content and water content are correct. The slurry is pumped from the slurry tanks to the storage tank, from which it is fed into the back of the kiln by revolving scoops, the amount being regulated by the official in charge termed the “Burner.” The rotary kiln consists of a revolving steel cylinder lined with refractory blocks. Its longitudinal axis is slightly inclined to permit the passage of the slurry along the kiln. The Rawang kiln is 315 ft. long and 9 ¼ ft. in diameter, increasing to 10 ½ ft at the “burning zone.” The rate of rotation is variable and is controlled by the burner. While the slurry is entering the upper end of the kiln, pulverised coal is being blown in at the firing end, thus drying, decarbonating and calcining the slurry, transforming it into “clinker” at temperatures around 2,500 degrees Fahrenheit in the burning zone. The final process The red hot clinker then passes into coolers from which it is transferred by conveyor to the clinker store. The clinker is conveyed to the mill where it is ground to become Portland cement. As the clinker is fed into the mill about 5 per cent of gypsum is added to prevent flash setting of the cement. The finished cement is pumped to storage silos from which it is fed to the packing plant where the packing machine automatically fills the four-ply paper bags to the specified weight of 112 lb and seals them. The bags are delivered by conveyor and chute to be loaded into rail trucks or lorries which convey it to distributors’ godowns or to the customers.

What’s in a name like Portland cement? THE manufacture of Portland cement is a comparatively recent development. Some form of cement was used to build the Pyramids in Egypt as far back as about 4000 B.C. The dome of the Pantheon, still standing, provides another early example. These “cements” were probably more akin to plaster of Paris, as we know it today, than a modern Portland cement. John Smeaton, builder of the original Eddystone lighthouse in England in 1756, was the first to find that clay mixed with limestone and fired made a good hydraulic cement. He declared that such a cement was equal in solidity and durability to the best marketable Portland stone. In 1824 Joseph Aspdin, of Leeds, found that by mixing finely pulverised chalk and clay, and burning the mixture at a very high temperature, he could produce clinker which, when ground, had setting properties if used with water, sand and stone to make “concrete.” When this material itself had set and hardened, it resembled Portland stone in colour and texture, so Aspdin called it “Portland” cement. This is the origin of Portland cement which is now known and used throughout the world. Its manufacture has become a scientific process employing all kinds of highly specialised machinery, but the essentials regarding raw materials remain the same.

Advert: Guthries—the oldest company in Malaya and a supporter of Malaya's Primary and Secondary Industries—welcomes this opportunity of congratulating MALAYAN CEMENT LIMITED whose products Guthries sell, on the opening of the second Kiln at Rawang Works. Branches at: S’pore, K.Lumpur, Penang, Ipoh, Malacca, Seremban, Kota Bharu, Kuala Trengganu, Kuantan, Port Dickson, Port Swettenham .

The Straits Times, 15 September 1959, Page 12 THE KILN—A MASSIVE BUT SENSITIVE ROTARY ASSEMBLY New slurry plant has capacity of 2,000 tons. It adds the finishing touches to an intricate process THE new slurry mixing plant which has not been filled. The slurry from the slurry mill is fed into the tank for proper mixing. The stirring arm operated by electric motors is seen in the picture. The tank has a capacity of 2,000 tons of slurry. IN all the massive assembly of gadgets that go to make up a cement factory the rotary kiln is the most sensitive piece of equipment. It is made up of several sections of revolving steel cylinders lined with refractory bricks. Most modern ITS PURPOSE: The most intricate finishing process in cement manufacture – the conversion of slurry to clinkers which can then be ground to cement powder. The kiln at Rawang is the most modern type. All its operations are directed from a control board. Big problem Getting it to Malaya from its place of origin in Germany posed a considerable problem. The kiln is 375 feet long and 10 feet in diameter. It is set at a gradient of one in 24 so that slurry fed into one end can pass down to the firing end. All the time the kiln is being rotated. To fire the kiln cleaned coal is used. This is ground up and the pulverised fuel is drawn into the kiln hollow by draught fans. As the slurry passes down to the firing end and dries out, it is decarbonated and calcinated. It is transformed into clinkers by the extreme heat at the firing end. The heat is in the measure of 2,500 degrees Fahrenheit. The clinker then has to be cooled—by air coolers. It is then taken by conveyor belts to the cement grinding mills for the final transformation into cement powder. The kiln is operated by a set of hand controls on the firing floor. Among the other things that have to be controlled are coal feed rate, kiln speed, slurry feed rate and the output of the induced draught fan. There are many indicators on the control panel showing the controller temperatures and draughts. The capacity This kiln can produce 150,000 tons of cement a year. The old kiln at the factory has been converted to make it more efficient and that now has a capacity of 108,000 tons.

Nearly all the raw materials for producing cement are local THE PROCESS of manufacturing cement is a vast undertaking. Some idea of the magnitude of operations carried out at the Malayan Cement Ltd. factory at Rawang can be gained from the raw material consumed in a year: Limestone – 320,000 tons; shale – 105,000 tons, electricity – 30,000,000 units; coal – 85,000 tons; gypsum – 13,000 tons; paper – 5,000,000 4-ply sacks Only gypsum (hydrous calcium sulphate, a mineral from which plaster of paris is made) and the paper sacks are imported. All the rest are produced in Malaya and the actual raw materials themselves are hauled to Rawang by Malayan Railway. Rawang was chosen as the site because of its large limestone deposits and its nearness to the source of coal and shale at Batu Arang.

AUTOMATIC PACKER AT THE FACTORY A fully automatic packing and dispatch plant is a feature of the factory. The four filling spouts can deal with 1,200 sacks per hour or 60 tons. The paper bags are placed on the spouts. The bags are filled automatically, weighed, sealed and fed on to conveyor belts.

Advert Hearty Congratulations to the MALAYAN CEMENT Ltd. on their success From THUM YEE (Dredge and Building Contractor) 15. Muntri Street, Penang. 3. Road 202, Petaling Jaya. Advert Congratulations to MALAYAN CEMENT LTD. on the occasion of the opening of their second kiln at RAWANG from WILLIAM JACKS & CO. (MALAYA) LTD. KUALA LUMPUR. Federation Branches: IPOH – PENANG – MALACCA – TAIPING – TELOK ANSON – KOTA BHARU – KUANTAN – SEREMBAN. Distributors of “TIGER” PORTLAND CEMENT. Advert PILING for factory extension FOR MALAYAN CEMENT LTD. BY SIME DARBY Advert We Supply INDUSTRIAL RUBBER PRODUCTS (TIGER BRAND) To MALAYAN CEMENT, LTD. RUBBER ‘U; RING COMPENSATING. WELLINGTON BOOTS (LONG & SHORT), RUBBER INSERTIONS, RUBBER BUSHES, RUBBER WASHERS, PISTON ROD RUBBER PACKING RING, HEAT RESISTING PRESSURE HOSE, FLOATING RUBBER BALL VALVES, ARMOURED PRESSURE & SUCTION HOSE, CANVAS REINFORCED RUBBER BUSHES, TRIANGULAR CABLE SUSPENDERS ETC. If It’s RUBBER, Consult Us SHUM YIP LEONG RUBBER WORKS LTD. Factory: 1 ¼ Mile, Kapar Road, Klang. Head Office: 404, Loke Yew Building, Kuala Lumpur. Sales Offices: Singapore, Kuala Lumpur, Ipoh, Butterworth, Penang, Segamat & Hong Kong. Suppliers of all Types of Rubber Products (Natural & Synthetic) to Industry.

The Straits Times, 16 September 1959, Page 5 Plan to seek small investors FINANCE MINISTER WELCOMES EXPANSION OF MALAYAN CEMENT WORKS A PLEDGE: GOVERNMENT WILL ENCOURAGE SETTING UP OF A MONEY MART, STOCK EXCHANGE KUALA LUMPUR, Tuesday. THE Federation Government will encourage the development of a money market and a stock exchange to accelerate industrial development. The Minister of Finance, Mr. Tan Siew Sin, said this today at the opening of the $7,500,000 extension works of Malayan Cement Limited at Rawang, about 18 miles from here. The extension was opened by the Sultan of Selangor, who later inspected the works. Mr. Tan said he believed that a lot more capital was available in this country for industrial development than was generally realised. “I am convinced that there are many people who have a few thousand dollars to invest but who find it difficult to invest it in anything, which they regard as safe,” he said. “As a result, one reads in the newspapers of thefts of cash from under pillows, cupboards and other odd places in ordinary homes. Reservoir “Or one reads of fragmentation of rubber estates, which is the result of the land hunger which still remains unsatisfied today, but which also indicates that there are many people who are prepared to pay excessive prices for almost any land because they regard such investment as safe, sound and solid. “All this goes to show that it should be possible for industrialists or would-be industrialists to tap what may be an enormous reservoir of capital, if they could convince the people of this country that investment in industry is as sound as investment in land and equally remunerative. Secondly, when the conviction is there, measures will have to be devised to channel this capital into institutions where it can be readily and easily tapped. “In this connection, the Government would welcome and indeed encourage the development of a money market and stock exchange, which could do much to accelerate the industrial development of this country” Mr. Tan said that the financing of industrial enterprises by means of capital subscribed by small investors was the most desirable form of capitalism because by this means Malaya could create a large and prosperous middle class with a real and enduring stake in the country. Tangible By this means also Malaya could create a property owning democracy and thus prove that democracy could achieve not only the material progress which, according to the tenets of totalitarianism, was not possible without regimentation, but at the same time preserve the dignity of the individual and the eternal value of life. Mr. Tan described the extension works as a concrete example of Malaya’s industrial development, and “I would say that we witness today a very tangible result of the Government’s declared policy in this field” The story of Malayan Cement Limited, he said, was one of efficient progress and enlightened management. He added: “It is a mark of confidence in the future prospects of the Federation that a decision was taken to extend the works. The extension project involves a second kiln of 120,000 tons capacity a year, two large grinding mills and other items of plant costing approximately $7 million. “This additional capital has come in equal shares from the company and from its 950 shareholders, 80 per cent of whom live in Malaya. Reserve. “The rated capacity of the extended works is now 220,000 tons a year, but the works is capable of producing over 250,000 tons - which is more than the present entire consumption of the Federation. “There is therefore, a reserve capacity to meet future expansion of the market.” Earlier the chairman of Malayan Cement Limited, Mr. John Drysdale, said that the company could produce enough cement to meet the entire requirements of the Federation. He added; “Unfortunately however, our output is restricted to what we can sell and we cannot yet make use of our full capacity owing to the importation of foreign cements. “We, however, are hoping that this restriction will soon be removed.” picture THE SULTAN of Selangor being introduced to Mr. H. J. Hamilton, works manager of the $7,500,000 extension works of the Malayan Cement Limited at Rawang, 18 miles from Kuala Lumpur, yesterday morning. The Sultan later declared open the extension works.—Straits Times picture.

The Straits Times, 21 September 1959, Page 10 MALAYAN COLLIERIES, LIMITED. (Incorporated in the Federation of Malaya) NOTICE is hereby given that the Forty-first General Meeting of the Company will be held at the registered office, Hongkong & Shanghai Bank building, Kuala Lumpur, on Thursday, 29th October, 1959 at 12 noon for the following purposes: - To receive and consider the balance sheet and accounts to 30th June, 1959, and the reports of the Directors and Auditors. To declare a dividend of 12 ½ cents per share and a bonus of 12 ½ cents per share, both less 40 per cent income tax for the year ended 30th June, 1959, payable on 29th October, 1959. To determine the Directors’ remuneration for the year ended 30th June, 1959. To elect Directors in place of those retiring To appoint Auditors for the ensuing year To transact any other business of an Ordinary General Meeting. NOTICE is also given that the share register will be closed from 16th October, 1959, to 29th October, 1959, both days inclusive, and the above dividend and bonus, if approved, will be paid to shareholders whose names appear in the Company’s register of members on 16th October, 1959. By Order of the Board J. A. RUSSELL & CO., LTD., Secretaries Kuala Lumpur, 21st October, 1959

The Straits Times, 22 September 1959, Page 12 CEMENT OUTPUT RISES AGAIN PRODUCTION of cement in the Federation of Malaya climbed to record heights in the first half of the year. Official figures show that output during the period totalled 75,600 tons, up 20,700 tons over the corresponding six months of 1958. The June production at 16,600 tons was 3,000 tons more than in the previous month and was also the largest amount produced so far this year. New project With the recent expansion programme carried out by Malayan Cement Ltd. at Rawang it is expected that output will soar further. Malayan Cement, the only factory of its kind in Malaya, has invested £7.5 million in the project which includes a second kiln, two grinding mills, extensions to existing buildings and ancillary equipment. The Rawang Factory has a rated capacity of over 200,000 tons of cement a year, although it can be worked up to produce 300,000 tons. The estimated annual consumption of cement in the Federation is about 250,000 tons and the company hopes to capture the entire market.

The Straits Times, 22 September 1959, Page 10 MALAYAN COLLIERIES TO PAY 25 CENTS: MART SURPRISE By Our Market Correspondent WHEN the Malayan Share Market re-opened yesterday a surprise was created by the improved rate of Malayan Collieries Ltd's distribution which is equivalent to 25 cents per fifty cents share. The distribution is made up of a dividend of 12 ½ cents per share and a bonus of 12 ½ cents for the year ended June 30. The latest payment is being made on a capital reduced to two million shares of 50 cents each, a return of half the share capital having been made to share-holders last year. The declaration came as a surprise because of the adverse conditions experienced in the past few years by the company due to the great reduction in production when the Federation Government switched over to diesel oil for operating the railways and power stations. Last year’s dividend was 5 per cent and at one stage post-war no dividends were declared, the company operating at a loss. The reason? Until the chairman’s statement is published, however, the reason for the increased rate of payment will not be known. It can be associated probably with the current prosperity of the sister company Malayan Cement Ltd. In which Collieries hold 663,750 founder shares of one dollar each. Yesterday the quotation jumped 16 ½ cents with business from $1.04 to $1.20 cum all. The Malayan Share Market generally was quiet and featureless with few significant price movements except in Collieries and a few other counters.

The Straits Times, 28 September 1959, Page 10 Malayan Collieries surprised the market by announcing a distribution of 25 cents per 50 cents share—12 ½ cents dividend and 12 ½ cents bonus—for the year to June 30. The payment is being made on a capital reduced by half. Last year 5 per cent was paid. The accounts and statement are not yet to hand. Business was done at $1.04 before the dividend announcement and by Friday was taken up to $1.27 cum all.

The Straits Times, 5 October 1959, Page 10 Malayan Cements were irregular from $1.65 to $1.75 to $1.73, but improved on balance to bring them into line with the sister company, Malayan Collieries whose dividend and bonus announcement has impressed the market. Collieries had business from $1.40 to $1.58 cd cb.

The Straits Times, 15 October 1959, Page 12 Malayan Collieries Coal production from Batu Arang during the last quarter was as follows: July 6,775 tons: August 5,015 tons, and September 7,301 tons.

The Straits Times, 15 October 1959, Page 12 CEMENT OUPUT Malayan Cement output for the last quarter was July 18,434 tons; August 16,429 tons; September 17,330 tons

The Straits Times, 23 October 1959, Page 1 Malaya's only coal mine to shut down in 4 months KUALA LUMPUR, Thursday. MALAYA'S only coal mine, the Malayan Collieries at Batu Arang, will stop operations in four months "unless something unforeseen happens to justify further development." Its Chairman, Mr. John Drysdale, estimates that the reserves of coal of 30,000 tons will last till February. He says in his statement to be presented at the annual meeting on Oct. 29 that customers have been informed of the position so that they can make arrangements for alternative fuel. The mine’s coal supply agreement with its associated company, the Malayan Cement Limited, will also expire as a result. Mr. Drysdale says: “Our remaining reserves of coal at present amount to 30,000 tons and it is estimated that these will last until February next year after which mining will cease unless something unforeseen happens to justify further development. No Alternative. “Our customers have been informed of the duration of the supply period so that they can make arrangements for alterative fuel and in this connection the coal supply agreement with our associated company, Malayan Cement Limited, expires on that date. “I wish to make it clear that there was no alternative to this arrangement as the colliery could not continue economically to meet the requirements of the cement company alone and their conversion to oil was inevitable. “Consideration of possible alternative uses for coal continued and while the possibilities of a fertiliser plant or a smelting plant are still with us, nothing of a definite nature has yet transpired” Employment on the mine has been reduced to three Europeans- the general manager, an engineer, and an accountant- and a total Asian staff and workers of 260. Sale of coal showed a further decrease- 60,470 tons compared with 100,000 tons in the previous year. Less Demand All underground operations ceased in July 1958 and coal mining since then has been restricted to available reserves in the open cast. All development has ceased as a result of the reduced demand for coal. Mr. Drysdale regards the profit of $463,046 for the year as “satisfactory,” especially as this is after writing off $350,000 included in last year’s account as development expenditure. He says: “The future outlook of the company is limited and mining operations are likely to cease when the present reserves of coal are used up but your directors will ensure that the remaining assets of the company are utilised to the best advantage of members.” The directors have recommended a dividend of 12 ½ cents a share and a bonus also of 12 ½ cents a share.

The Straits Times, 23 October 1959, Page 13 Collieries’ Future Forecasts about the possible liquidation of Malayan Collieries current in the market for some weeks are borne out in the annual report published yesterday. The chairman, Mr. J. Drysdale, tells shareholders remaining reserves of coal at present amount to 30,000 tons and it is estimated that these will last until February next year. After that mining will cease unless something unforeseen happens to justify further development. Mr. Drysdale states: “The future outlook of the company is limited and mining operations are likely to cease when the present reserves of coal are used up, but the directors will ensure that the remaining assets of the company are utilised to the best advantage of members who will be kept advised of any future intentions.” The profit for the year ended June 30 was £463,046. The sum of $100,000 was received from the sale of plant and machinery no longer required. The sale of coal fell from 100,000 tons to 60,470 tons. As published on September 22 the company is paying a dividend of 12 ½ cents and bonus of 12 ½ cents. Business was done at $1.55 and $1.56 x all yesterday.

The Straits Times, 24 October 1959, Page 12 The balance sheet of another industrial company, Malayan Collieries Ltd. For the year to June 30 showed a net profit of $440,546 or 25.7 per cent. Net liquid assets at $2,060,134 were equivalent to 60 cents per 50 cent share and stores totalled $667,389 or 19.4 cents per share. Founder shares in the sister company Malayan Cement Ltd. at balancing date were worth $1,065,319 or 31 cents per share. Business was done at $1.56 and $1.60 ex all.

The Straits Times, 26 October 1959, Page 10 The possibility of the liquidation of Malayan Collieries in the next few months when existing reserves of coal run out took the shares from $1.52 to $1.60, having regard to their favourable break-up value. The balance sheet for the year to June 30 showed a net profit of $440,546 or 25.7 per cent. Net liquid assets at $2,060,234 were equivalent to 60 cents per 50 cent share and stores totalled $667,389 or 19.4 cents per share. Founder shares in the sister company Malayan Cement Ltd. at balancing date were worth $1,065,319 or 31 cents per share.

The Straits Times, 31 October 1959, Page 12 We have pleasure in announcing that we have appointed MESSRS. SIM LIM CO. LTD. as one of our Distributors for Tiger Cement. MALAYAN CEMENT LIMITED, KUALA LUMPUR.

The Singapore Free Press, 10 November 1959, Page 10 MTUC MOVE TO SAVE MINE KUALA LUMPUR, Tues. Batu Arang—Malaya's coal mining town with a bleak future—will be one of the main subjects of discussion by delegates from 75 unions attending the ninth annual conference of the Malayan Trade Union Congress this weekend. The only coal mine in the country, the Malayan Collieries is due to close down in three month. The chairman, Mr. John Drysdale, has estimated that the reserves of coal of 30,000 tons will last only until February. The township of Batu Arang, consisting of about 2,000 people, depends upon the Collieries and its workers. A resolution to be discussed by the MTUC conference says that Government should take immediate measures for industrial development at Batu Arang.

The Straits Times, 8 December 1959, Page 6 Colour bar? Hospital chief still says no KUALA LUMPUR, Mon. Mr. John Drysdale, chairman of the Lady Templer Tuberculosis Hospital's board of governors, today again denied that a colour bar existed at the hospital. He was replying to a charge made yesterday by 38 assistant nurses that there had been instances of discrimination against Asian members of the hospital staff. The charge was first made by Mr. D. R. Seenivasagam, leader of the People’s Progressive Party in the House of Representatives last week. In a press statement yesterday the nurses challenged Mr. Drysdale to make a full enquiry into the state of affairs. Mr. Drysdale said today: “I still say that no colour bar exists in the Lady Templer hospital. “Although a consultative machinery exists at the hospital, I can definitely say that no representation has so far been made by the hospital staff about the matter.” In a statement this evening Mr. Seenivasagam called on Mr. Drysdale and his committee to “resign forthwith” and said that a commission should be set up to inquire into the complaints and conditions of service in the hospital.

The Straits Times, 9 December 1959, Page 11 MENZIES: AUSTRALIA IS INTERESTED IN MALAYA’S GROWTH AND SUCCESS Mr Menzies said: "We have discussed such matters as medical training and engineering training and various forms of administrative assistance. "The whole matter may be summed up by saying that we want to help if and when and where we can." Mr. Menzies final words summed up also the tenor of his feelings about his visit: "My wife and I have felt completely at home among you." This morning, after a visit to Parliament House, Mr Menzies drove to the Cenotaph to lay a wreath on the war memorial. A separate morning programme of visits to the Lady Templer Tuberculosis Hospital at Cheras and the headquarters of the National Association of Women's Institutes, Petaling Jaya, was arranged for Dame Pattie Menzies. Interest With its Australian associations, the pink-walled hospital on a hilltop had a special interest for her. It is staffed by Australian nursing sisters under the Colombo Plan. Scholarships have also been awarded under the Plan for training Malayan girls in nursing and in radiography in Australia. Dame Pattie, who was accompanied by Datin Norashikin Ismail, wife of the Minister of External Affairs, was met on her arrival by the chairman of the Board of Governors, Mr. John Drysdale. An Australia – trained radiographer, Miss Chin Tuck Yun, presented her with a bouquet. With a fellow Australian Matron D. M. Stasinowsky at her side, Dame Pattie, in a grey and white striped silk dress, moved through the wards, showing a close interest in everything. In the female ward, she lifted the hearts of a dozen inmates with the sincerity of her remark: "You really look quite well – almost better in fact." Radios In the male ward, she showed keen interest in the built in individual bedside radios with earphone attachment provided for each patient. The gleaming kitchen, with lunch preparations of different racial diets underway, caught Dame Pattie’s attention most. Her verdict on the hospital "I am terrifically impressed."

The Straits Times, 15 December 1959, Page 12 • Wagon is derailed at Rawang • KUALA LUMPUR. Mon. -An empty wagon from a goods train was derailed one and a half miles south of Rawang station and held up rail traffic for about two hours today. • The wagon was one of 56 on a goods train which was going to the Malayan Cement factory at Rawang. • Wagons derailed on Dec. 8 were also on a goods train scheduled to carry cement from Rawang to Kuala Lumpur. • On its side • At 11.15 a.m. today, the seventh wagon from the rear of the goods train jumped the rails and ended up on its side. The six wagons behind were not affected. • The local passenger rain from Gemas, which was scheduled to arrive at Ipoh at 6.15 p.m., was expected to be delayed for about two hours. It was stopped at Kuang. • A breakdown crew went to the scene soon after the derailment and began to repair the slightly damaged tracks. • An engine hauled the last six wagons at the rear of the train back to Kuang. The engine with 49 wagons still coupled proceeded to the Malayan Cement factory.

The Straits Times, 28 December 1959, Page 24 MALAYAN CEMENT, LIMITED (Incorporated in the Federation of Malaya) NOTICE IS HEREBY GIVEN that an Extraordinary Meeting of the above named Company will be held at the Registered Office of the Company, Hongkong and Shanghai Bank Building, Kuala Lumpur, on the 22nd day of January, 1960. at 2.15 0’clock in the afternoon for purpose of considering, and if thought fit, passing the following Resolution as a Special Resolution: - THAT the Articles of Association of the Company be altered as follows: - (1) Article 85. By substituting in the fourth line for the words “two” and “fuve” the words “four” and “seven” respectively. (2) Article 86. By substituting in the fifth and sixth lines for the words “three” and “two” the words “four” and “three” respectively (3) Article 100. By substituting in the fourth line for the word “three” the word “four.” (4) Article 101. By substituting in the second line for the word “two” the word “three.” The object of these alterations is to permit the appointment of two locally domiciled Directors. By Order of the Board J. A. Russell & Co., Ltd Secretaries, Dated the 28th day of December, 1959.

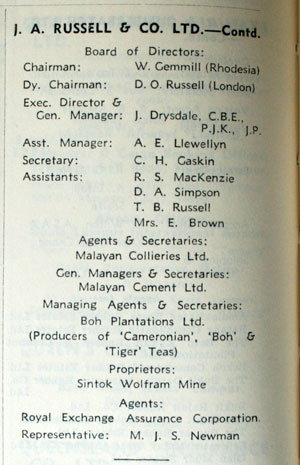

J. A. RUSSELL & CO., LTD.

Board of Directors

Chairman W. Gemmill (Rhodesia)

Dy. Chairman D. O. Russell(London)

Exec. Director

& Gen. Manager J. Drysdale, C. B. E., P. J. K., J. P.

Asst. Manager A. E, Llewellyn

Secretary C. H. Gaskin

Assistants R. S. McKenzie

D. A. Simpson

T. B. Russell

Mrs E. Brown

Agents & Secretaries: Malayan Collieries, Ltd.

Gen. Managers & Secretaries: Malayan Cement Ltd.

Managing Agents & Secretaries: Boh Plantations, Ltd.

(Producers of ‘Cameronian’ ‘Boh’ and ‘Tiger’ Teas)

Proprietors : Sintok Wolfram Mines.

Agents:

Royal Exchange Assurance Corporation.

Rep: M. J. S. Newman

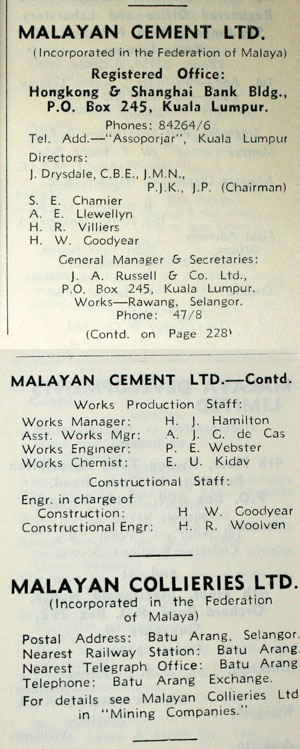

MALAYAN CEMENT LTD.

(Incorporated in the Federation in Malaya)

Registered Office:

Hongkong & Shanghai Bank Bldg.,

P. O. Box 245, Kuala Lumpur

Phones: 84264/6

Tel. Add.—“Assoporjar”, Kuala Lumpur

Directors:

J. Drysdale, C. B. E., J. M.N., P. J. K, J.P. (Chairman)

S. E. Chamier

A. E. Llewellyn

H. R. Villiers

H. W. Goodyear

General Manager & Secretaries:

J. A. Russell & Co., Ltd. P. O. Box, 245, Kuala Lumpur

Works—Rawang, Selangor.

Phone: 47/8

Works Production Staff:

Works Manager: H. J. Hamilton

Asst. Works Mgr: A. J. G. de Cas

Works Engineer: P. E. Webster

Works Chemist: E. U. Kidav

Constructional Staff

Engr. in charge of

Construction: H. W. Goodyear

Costructional Engr: H. R. Woolven

MALAYAN COLLIERIES, LTD.

(Incorporated in the Federation of Malaya)

Postal Address: Batu Arang, Selangor.

Nearest Railway Station: Batu Arang

Nearest Telegraph Office: Batu Arang

Telephone: Batu Arang Exchange.

For details see Malayan Collieries Ltd in " Mining Companies"

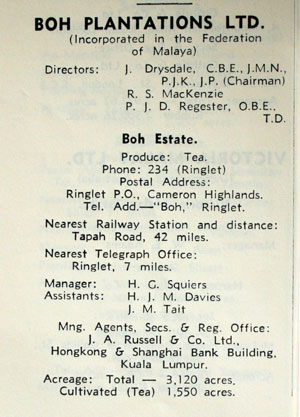

BOH PLANTATIONS, LTD.

(Incorporated in the Federation in Malaya)

Directors:

J. Drysdale, C. B. E., J. M. N., P. J. K., J. P. (Chairman)

R. S. MacKenzie

P. J. D. Regester, O. B. E., T. D.

Boh Estate.

Produce: Tea

Phone: 234 (Ringlet)

Postal Address:

Ringlet P.O., Cameron Highlands.

Tel. Add.-"Boh " Ringlet

Nearest Railway Station and distance:

Tapah Road, 42 miles.

Nearest Telegraph Office:

Ringlet 7 miles.

Manager: H. G. Squiers

Senior Assist: H. J. M. Davies

J. M. Tait

Mng. Agents, Secs. & Reg. Office: J. A. Russell & Co., Ltd. Hongkong and Shanghai Bank Building, Kuala Lumpur

Acreage—Total 3,120 acres. Cultivated (Tea) 1,550 acres

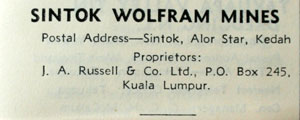

SINTOK WOLFRAM MINES

Postal Address—Sintok, Alor Star, Kedah

Proprietors:

J. A. Russell & Co., Ltd. P. O. Box, 245,

Kuala Lumpur