For the descendents of Richard Dearie and his son John Russell

Cement.

As early as 1908 George Russell was unhappy with the quality of the cement provided by the Government Stores. As manager of the Federated Engineering Company, when he tendered to build the new service reservoir at Welds Hill, he asked to be allowed to supply his own cement instead of buying it from the State Store. He argued that it would be cheaper and he could ensure the quality. If the contract insisted on the use of cement from the Government he asked that the Federated Engineering Company be relieved of responsibility for its quality.

In his speech at the 16th A.G.M. of Malayan Collieries in 1930, Archie Russell was confident that a cement industry could be set up: "In addition to this problem in the economics of agriculture, your Board has been investigating ways and means of extending the demand for its Rawang coal. As an aid thereto, the establishment of coal consuming industrial plants has been, and is being, very seriously, and, in the case of cement manufacturing plant, very thoroughly, studied. With regard to this latter industrial undertaking, there are still some essential details to be settled before a decision can be arrived at for or against the enterprise; but at the moment, the prospects look encouraging. Our investigations, so far as they have gone to date, have shown that, thanks to the concentration of raw material, cheap power and technical organisation which we possess at Batu Arang, and to our not needing to incur any promotion or vendor’s or other such burdening costs we are likely to be in a favourable position to establish the industry on an exceptionally sound basis and to manufacture a product of the highest standard of quality at prices competitive with those of the imported article."

By 1931 at the A.G.M. of Malayan Collieries, Archie said he had continued to investigate subsidiaries for the Colliery one of which could be cement manufacture, in order to make use of some of the waste spoil from coal mining. The Straits Times commented in December: " The chairman’s speech at the annual meeting of Malayan Collieries is always one of the most interesting in the Malayan investment field, but it may contain unusually interesting and important news next year. Last month a duty was imposed on cement imported into the Federated Malay States which increased the cost of this commodity by between thirty and forty per cent. At the Collieries meeting last March Mr. Russell said: “The investigations into the cement manufacturing industry were completed, and we now have all the facts and figures necessary to enable us to formulate a definitive proposition for the consideration of shareholders, if or when conditions improve. Notwithstanding the present depression and consequent shortage of money for new public and private works, we feel that potential business will eventually justify the establishment of modern works as a department by your undertaking, provided such works are assured of full support and of some small measure of protection against any gross unfair competition from goods dumped upon the local market by non British producers. Such manufacturers enjoy a highly protected domestic market, which protection in their own country enables them to dump their factory surpluses upon our unprotected local market at considerably below actual cost. Given some measure of protection against such dumped goods, which dumping must otherwise inevitably strangle all industrial markets of the east, we feel that we could make cement manufacture within the F.M.S. an attractive proposition to the ultimate benefit of the country, particularly in that it would help to remedy Malaya's dangerous adverse balance of trade.” There have been other attempts at cement manufacture in this country. Kenneison Brothers, at Batu Caves, near Kuala Lumpur, tried a mixture of limestone and mangrove mud, but the venture was not commercially successful. This is understandable when one recalls the statement made by the Federal Council last month that Japanese cement is being shipped to Singapore at cost price as ballast. In Singapore coral and mangrove mud have been used for cement manufacture. “There are great possibilities for cement manufacture in Malaya” says Mr. J. B. Scrivenor in his recent book, “ but so far it has not proved easy to get limestone sufficiently free from magnesia and other ingredients close together, while good cement can be obtained overseas at fair prices”

In 1932 the Collieries Director's annual report for 1931 stated: "In connection with the proposed manufacture of Cement, prospecting rights were also obtained over a limestone deposit within a short distance of Batu Arang, and the necessary preliminary surveys, sampling and analyses were carried out. Final sampling is now in progress with satisfactory results."

By the time of the 1932 A.G.M. Archie was optimistic about his plans for cement: "“A Cement Industry. Apart from the demand for coal for steam-raising purposes which lies beyond our distance-radius of price effectiveness, probably the largest potential consumer within Malaya would be a cement manufacturing industry, the establishment of which it is the hope of your board either to undertake or to foster. Since last addressing you, the Government of the F.M.S. has imposed a duty on the importation of cement, apparently with the dual purpose of raising revenue and of helping in the establishment of a local industry. We have, as you know, already conducted extensive investigations into our resources and our raw materials- having had the latter commercially converted into cement in England and on the Continent- and we possess very full expert opinion upon all relevant points. The only step which we might still take is to get an actual visit made to the spot by a cement expert. We have, accordingly, arranged for such a visit by a well know cement consulting engineer who is due to arrive in the country today. (March 31st. 1932 ) After a study of local conditions he will prepare for us a concluding report upon our exact position, especially in regard to our ability to compete with markets outside of the F.M.S. on which we are relying to absorb any surplus capacity of our proposed factory. Subject to transportation costs to export points, we ourselves believe that we should be able to compete with all cements except those which are recklessly dumped, and if our consulting engineer, as a result of these very careful investigations of every aspect of the matter on the site, confirms this view, we hope to be able very shortly to formulate a definite scheme. Lest, however, anxiety be felt by some shareholders at the prospect of being called upon to subscribe considerable amounts of fresh capital for the cement works at a time of great financial stringency, I may say that it is not the present intention of your board to suggest such a course." The leader article in the Straits Times of 15 April 1932, noted: "it is most encouraging to see a company of the financial strength of Malayan Collieries devoting itself to the study of local manufacturing possibilities. Its action in bringing out a cement expert to complete the inquiries which have already been made into cement manufacturing possibilities at its Batu Arang property are a case in point. There have been cement factories in this country but there are none today. The modern uses of cement demand the most accurate processes of manufacture, such as will give architects and engineers complete confidence in the quality of the product, and we may be thankful that the examination of this Malayan problem is in such competent hands."

According to Rita Drysdale it was in 1932 that "following up J. A.’s idea Robbie (H.H. Robbins) and John Drysdale looked into development for the cement factory. Robbie went to London to interview cement people and John Drysdale was appointed Robbie’s alternative.

However the plans were put on hold by waiting for the Government's decision, the slump and by Japanese exports. The Company report in March 1933 stated: "Investigations into all phases of the manufacture of cement, and its transportation and marketing have been completed. As such matters as royalties excise duties, leases and way leaves are involved, our complete proposals have been placed before Government and we hope for decisions at an early date." H.H. Robbins reading Archie's planned speech to the A.G.M. in 1933 said: " By far the largest and most important undertaking which we have under consideration is, of course, the proposed cement works, with its quarry and transportation system. We have indicated in our report to you that the whole of our proposals have been submitted for the consideration of Government, and as the result of this consideration has not yet been conveyed to us, it would at this stage be inadvisable for me to make any other than general comments. The condition, of course, of the cement markets in the East is at present little short of chaotic, due to the general curtailment of building works and to the organised dumping of Japanese cement, but we believe that the present state of affairs cannot last, and the position is being carefully watched. In the meantime pending the decision of Government, everything which can be done by us, short of actually placing contracts, has been done. The utmost caution has guided us from the commencement of our investigations, and this consideration will continue to guide us to the end. In the financing of the undertaking, should it mature, the strictest economy will be practiced, and due regard will be had for the average shareholder’s command of new capital. Technically, the works which we have under consideration are quite the last word in proved efficiency; while financially, the closely estimated initial capital expenditure per ton of annual production is as favourable as anything yet achieved in the installation of similar plant. These factors, coupled with our favourable concentration of raw materials, existing organisation and the proposed facilities for export, require only an assurance for the demand for the product, at prices based upon the most favourable possible production costs plus a reasonable profit, to assure us of satisfactory returns. That the demand has in the past existed for several times our proposed initial production, statistics will prove. Cement is so fast becoming one of the staple requirements of civilization that it is inconceivable that the demand will not revive, and if this view be accepted, the whole matter is reduced to a consideration of competition. As I have already mentioned, with our proposed facilities, we have no doubt of our favourable position to compete with the production of any country, as long as that production is sold at something above its actual cost plus freight. Against dumping, we, in common with other manufacturers, cannot profitably compete in open markets. In referring to dumping, I naturally discriminate between such and legitimate keen competition. So much for the problem and considerations which confront us in arriving at a decision in connection with our current cement works proposals. The whole matter is constantly before us, and it is hoped that a member of your board will shortly confer with our consulting engineers in London, and with the principal tenderers of the supply of the plant. You will be advised immediately any decision is arrived at, and in the meantime, I repeat that it will not I any case be necessary for you to earmark any capital for this project, as until such time as it may be considered wise to make a new issue of shares, finance can almost certainly be arranged."

At the 20th AGM in 1934 Malayan Collieries were suffering from Archie's death and the effects of the depression. H.H. Robbins had taken over as chairman. They had decided that overproduction and Japanese exports means that co- production was the safest way forward: "The cement works, the possibilities of which we have investigated, would utilise for power and kilns very large quantities of coal, considerable quantities of shale- which is a waste product of the stripping of coal- and large quantities of limestone which would consume power in production. All these undertakings being grouped provide an excellent spread for those overheads and charges which are fixed whether one department or many are involved, and all the products when transported over the F.M.S. Railways, represent an increase in traffic which in turn has the effect of increasing the consumption of our coal.... A considerable amount of further thought and work was devoted to the matter of the proposed cement works at Batu Arang. Under the conditions which existed throughout the year, your Board were not disposed to place before you a recommendation to proceed with installation. With most industries of the world, both primary and secondary, over-provided with productive capacity, or at least with productive capacities considerably in advance of demand, it seemed unsound to advise installation of this new plant. Added to this position, which will probably right itself in due course, was the trend of Industrial development in Japan, or, to quote a Japanese authority, “ the change in Japan from a negative trade policy, calculated to protect home industries, to a positive policy, designed to systematise exports and to assist producers to overcome foreign suppressive measures against Japanese goods. The development of the Japanese exports has been truly amazing, and while it is evident that the ravaging of the markets of the world, with the combined aid of low wages direct and indirect subsidies and heavily depreciated exchange, cannot go on for ever, the Japanese manufacturer, while he enjoys the unstinted support of a steady and vigorous people, accustomed to and for the time satisfied with simple conditions, must inevitably set entirely new standards of values in manufactured goods at least here in the East. In all your Board’s deliberations this aspect has been very predominately to the fore. While it is agreed that, subject to demand for cement within Malaya, the proposed manufacturing plant could be expected to give an entirely satisfactory account of itself, the conditions ruling and the low visibility which throughout the year frustrated attempts to take a normal and legitimate commercial view of the future, did not ensure those auspices for the establishment of a new industry which the undertaking called for. While the matter was still under consideration, we were asked to consider a proposal for the transfer to Batu Arang of a British plant which was quite recently installed not very far distant from Malaya. A proposed basis for negotiations was drawn up for the consideration of the company concerned, and this provided for the ultimate abandonment of production on the present site, and the supply of requirements of the territory which the plant thereon was designed to serve, from the plant as re-erected at Batu Arang. Question of Site. Though your Board was attracted by a proposal which might reasonably be described as a transfer of production from a less economical site to amore economical one, thus avoiding a nett increase in productive capacity and competition between British interests, and at the same time definitely increasing this company’s prospective demand, it was finally decided not to develop the proposal for recommendation to shareholders for adoption by your company alone. Feeling that the principle was sound, and having regard to the fact that the primary object of your Board was to develop a demand for coal which is the main product of your undertaking, your Board have indicated to the Company referred to, a way in which we might co-operate with them in arranging for the transfer of their plant to Malaya. If this proposal should develop, each shareholder will be given an opportunity to participate according to his own wishes in the matter, while the company’s contribution and liability will be strictly limited to that which can be safely undertaken without resorting to the raising of capital, or in any way interfering with its dividend paying capacity.”

By 1935 they were no further forward although H.H. Robbins said at the 21st AGM this was an advantage:" Proposed Cement works. The position with regard to the proposed cement works is very much the same as it was at the time of my last reference. We are watching the position carefully and nothing from a technical point of view is being lost by the delay, as the design of the cement making machinery is undergoing changes which may be of far reaching significance, and meantime threaten comparatively recent plants with obsolescence of important and costly items of plant”. By 1936 he said: “ With regard to the proposed cement works, the position remains much as it was when I last addressed you, though the matter has not been dormant in the interval.” Cement was not mentioned in the annual report of 1937 as covered by the Straits Times; the colliery has seen profits jump so perhaps they were less interested in subsidiary industries. However by 1939 Robbins said: "The position regarding the proposed installation of a cement manufacturing plant here in the F.M.S. in conjunction with experienced British Interests is still unfinished. While having regard to the trend of political developments, the establishment of a plant to render Malaya self sufficient in the matter of its cement supplies must be of immense advantage to the country, that same trend may or may not enhance the value of the proposed undertaking as an investment, and the position will call for a very careful review before any definite step can be taken.” John Drysdale later said that they had ordered a cement kiln and it was actually on its way out to Malaya at the beginning WW2 but the ship was sunk by enemy action.

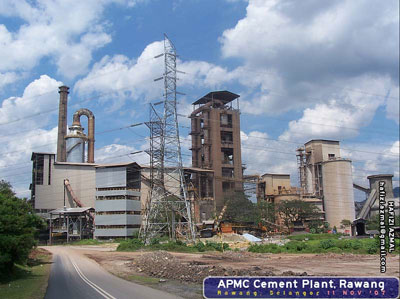

After the Japanese invasion in WW2 the colliery was taken over and both H.H. Robbins and John Drysdale were imprisoned. H.H. Robbins died in the camps but John Drysdale survived and returned to Malaya in 1946 to re-form J. A Russell and carry out the plan for cement manufacture. The cement company was set up in association with Associated Portland Cement Manufacturers in London and registered in November 1950, 20 twenty years after Archie's first proposals. It advertised its first General Meeting on 14th August 1951 at the Hongkong and Shanghai Bank Building, with J. A. Russell and Co. Ltd. acting as General Managers and Secretaries. John Drysdale explained at the meeting that they had intended to proceed with the floatation in 1950 but felt unable to due to the Korean War. Work on the site had started in June and production would begin in early 1953. By December the Straits Times reported:"• The works site has been prepared, security measures installed and access roads and rail sidings are now being constructed • The first group of 32 permanent quarters for the workers is nearing completion and tenders for staff houses are under consideration. The site for these has already been cleared. • A chief construction engineer from the Associated Portland Cement Manufacturers in Britain is in charge of all the technical developments. • Orders for work and materials have been placed locally but the bulk of the plant and equipment have been ordered from Britain."

.

"The Sultan of Selangor being introduced to Mr. H. J. Hamilton, works manager of the $7,5000,000 extension works of the Malayan Cement Limited at Rawang, 18 miles from Kuala Lumpur, yesterday morning. Making the introduction is Mr. John Drysdale chairman of the company. The Sultan later declared open the extension works. -Straits Times picture." The Straits Times, 16 September 1959, Page 5

From the left: The Sultan, John Drysdale, The Minister of Finance: Mr. Tan Siew Sin, Mr. Hamilton, Alan Llewellyn , Douglas Waring and ?

Photograph by Poon Cheng Cheong 44, KG. Attap.KL

John Drysdale giving his speech.

Photograph by Poon Cheng Cheong 44, KG Attap.KL

MALAYAN CEMENT LIMITED

TO COMMEMORATE THE OPENING OF THE WORKS EXTENSION BY

HIS HIGHNESS

SULTAN HISAMUDDIN ALAM SHAH AL HAJ

D.M.N. D.K. (BRUNEI)

ON

TUESDAY SEPTEMBER 15th 1959

From The Straits Times, 16 September 1959, Page 5:

" Plan to seek small investors FINANCE MINISTER WELCOMES EXPANSION OF MALAYAN CEMENT WORKS • A PLEDGE: GOVERNMENT WILL ENCOURAGE SETTING UP OF A MONEY MART, STOCK EXCHANGE • KUALA LUMPUR, Tuesday. • THE Federation Government will encourage the development of a money market and a stock exchange to accelerate industrial development. • The Minister of Finance, Mr. Tan Siew Sin, said this today at the opening of the $7,500,000 extension works of Malayan Cement Limited at Rawang, about 18 miles from here. • The extension was opened by the Sultan of Selangor, who later inspected the works. • Mr. Tan said he believed that a lot more capital was available in this country for industrial development than was generally realised. • “ I am convinced that there are many people who have few thousand dollars to invest but who find it difficult to invest in anything, which they regard as safe,” he said. • As a result, one reads in the newspapers of thefts of cash from under pillows, cupboards and other odd places in ordinary homes. • Reservoir • One reads of fragmentation of rubber estates, which is the result of the land hunger which still remains unsatisfied today, but which also indicates that there are many people who are prepared to pay excessive prices for almost any land because they regard such investment as safe, sound and solid. • All this goes to show that it should be possible for industrialists or would-be industrialists to tap what may be an enormous reservoir of capital, if they could convince the people of this country that investment in industry is sound as investment in land and equally remunerative. • Secondly, when the conviction is there, measures will have to be devised to channel this capital into institutions where it can be readily and easily tapped. • In this connection the Government would welcome and indeed encourage the development of a money market and stock exchange, which would do much to accelerate the industrial development of this country” • Mr. Tan said that the financing of industrial enterprises by means of capital subscribed by small investors was the most desirable form of capitalism because by this means Malaya could create a large and prosperous middle class with a real and enduring stake in the country. • Tangible • By this means also Malaya could create a property owning democracy and thus prove that democracy could achieve not only the material progress which, according to the tenets of totalitarianism, was not possible without regimentation, but at the same time preserve the dignity of the individual and the eternal value of life. • Mr. Tan described the extension works as a concrete example of Malaya’s industrial development, and ‘I would say that we witness today a very tangible result of the Government’s declared policy in this field” • The story of Malayan Cement Limited, he said was one of efficient progress and enlightened management. • He added: It is a mark of confidence in the future prospects of the Federation that a decision was taken to extend the works. • The extension project involves a second kiln of 120,000 tons capacity a year, two large grinding mills and other items of plant costing approximately $7 million. • This additional capital has come in equal shares from the company and from its 950 shareholders, 80% of whom live in Malaya. • Reserve. • The rated capacity of the extended works is now 220,000 tons a year, but the works is capable of producing over 250,000 tons - which is more than the present entire consumption of the Federation. • There is therefore, a reserve capacity to meet future expansion of the market. • Earlier the chairman of Malayan Cement Limited, Mr. John Drysdale, said that the company could produce enough cement to meet the entire requirements of the Federation. He added; unfortunately however, our output is restricted to what we can sell and we cannot yet make use of our full capacity owing to the importation of foreign cements. • We, however, are hoping that this restriction will soon be removed.”

On 6 July 1953 the factory was officially opened with Mr. G. F. Earle, chairman of Association Portland Cement Manufacturers. Ltd. arriving in Malaya for 10 days for the opening ceremony. "GER. TEMPLER today described the factory built by Malayan Cement. Ltd., at Rawang, 20 miles from Kuala Lumpur, as "exactly the kind of project this country needs to strengthen and consolidate its economic structure." The factory, which cost $10 million has been financed jointly by Malayan Cement Ltd and the Associated Portland Cement Manufacturers Ltd. of Britain. Sir Gerald flew from King’s House by helicopter to declare the factory open. "The decision of a firm of such high international repute as the Associated Portland Cement Manufacturers Ltd to invest in this new enterprise, demonstrates the returning confidence of British interests in the economic future of Malaya, he said. That confidence will in itself do a great deal to contribute to our prosperity. But it is equally heartening that such a ready response has been met with from local investors who have raised half the capital. This shows the confidence of the Malayan people in British firms and the willingness of Malayans to take part in schemes from which both countries will profit.” Young Malayans would have the chance to be trained in modern industrial techniques and business methods. Mr. J. Drysdale chairman of Malayan Cement Ltd. said that workers of all races in Malaya had contributed much to building the factory. “Their combined efforts and harmonious working augur well for the future of Malaya and the building of a united Malayan nation in which industries such as this will play a very important part.” The factory would employ about 120 workmen and would produce 100,000 tons of cement yearly."

Advertisements for the " Tiger Brand" cement appeared in the Straits Times in August 1953.

By 1954 Malayan cement shares were in demand, going for $1.33 while Malayan Collieries had sunk to 74 cents. In 1956 John Drysdale, now chairman of directors of Malayan Collieries was given the CBE for outstanding public service in Selangor over a period of more than 20 years. At the 7th AGM of Malayan Cement Ltd in March 1957 Drysdale, as chairman, announced an expansion of the works. There was still a threat from Japanese competition. On 20 April 1957 Drysdale 's letter to the Straits Times said: " You quoted the other day the remark of a Japanese visitor to the effect that Japan knew that if she did not consider starting a cement factory in the federation, other countries might do so. As chairman of Malayan Cement Ltd. I pointed out only a few days before that my company is now producing over 100,000 tons of cement a year and is taking active steps to double its production. I might add that when demand for cement justifies it, the company will consider further expansion, and such expansion is allowed for in its project plans. JOHN DRYSDALE, Kuala Lumpur."

By August 1957 they announced the first stage of their expansion in large half page advertisements in the Straits Times.

Top right and right: Sir Gerald Templar and John Drysdale speaking on 6 July 1953 at the opening of Malayan Cement.

Left: The cement packing machine.

Above: The staff of Malayan Cement Ltd in Rawang taken on October 14, 1967. Thanks to Malkeet Singh Gill for the photograph. His late father Gurdial Singh, who worked there from 1962 until 1974, can be seen standing in the middle of the middle row behind Bernard Crane , Maurice A. Easton and Jack Davies. The story of Malkeet's time at the firm can be read here.

Back Row Left to Right:

V. K. Nair- Yard Foreman, A. J. Stellus-Packing Plant Foreman, Arjan Singh -Fitting-Shop Foreman, Venugopal Nair/Gopenath? -Chemist , William Harry-Quarry Foreman , Wong-MRD Foreman.

2nd Row Left to Right:

Chow Hock Chor- Store Keeper, Tan See Bew- Wages Clerk, Lim Hock Eng- Clerk, (?? Production Trainee), Ramachandran- Despatch Clerk, Vengdasalam- Laboratory Assistant , Ali/Nadarajah?- Quarry Assistant, Ng Chee Meng- Electrical Engineer, ?Perera T. Verghese-Quarry Assistant, Loh Kok Weng-Assistant Engineer (mechanical) ,Dass-Chemist, P.C. Thomas- Cashier, Mukandan-Assistant Dresser (Medical)

3rd Row Left to Right:

Lim- Trainee Engineer, for a short period , K. Thomas-Works Chemist, Raghoothaman-Clerk, A .V. B. Menon-Chemist, Abdullah Saunan-Clerk, Amir Hashim- Works Dresser( medical) , K. Muthu-Master Kiln Burner, N. Gurdial Singh-Chief Wages Clerk, Ng Sai Seng- Assistant Electrical Engineer, S.K. Nair- Mill House Foreman , Wan Hussain Hababa-Welfare Officer, N. S. Chen- trainee, Rahman Jantan-Desptach Clerk, Abdullah-Trainee.

Front Row Sitting Left to Right:

Ronnie/Tommy Atkinson-Shift Foreman, Mrs. K.M. Joseph-Manager's Secretary, Mrs. Loh Weng Lin-Telephonist, Miss S. N. Devi - Typist, Bernard D. Crane- Assistant Works Manager, Morris A. Easton -Works Manager, Jack Davies- Works Engineer, K. M. Joseph- Works Accountant, Wong -Assistant to Works Manager, Jamal Musa-Shift Foreman.

Thanks to Malkeet Singh Gill and Malcolm Llewellyn for their list of names which differ slightly and have been reconciled.