For the descendents of Richard Dearie and his son John Russell

The F.M.S. Chamber of Mines Magazine, No, 5, January 1918 and MALAYAN COLLIERIES. [Articles] The Straits Times, 26 September 1917, Page 11

MALAYAN COLLIERIES. Directors’ Annual Report The report of the directors of Malayan Collieries, Limited, for the year ended June 30, 1917, states: - On October 20 a final call of 75 cents per share was made on ordinary shares, thus making these $10 fully paid. During the year application was made for the conversion of a further 280 acres to mining lease (making a total area under lease of approximately 2,027 acres) whilst the prospecting licence was renewed over the balance of the Concession. Coal sales totalled 135,663 tons as against 50,042 tons for the last financial year, an increase of 85,621 tons, or 171 per cent. Prospecting was continued throughout the year with satisfactory results. In order to expedite this work an extra and larger diamond drill set was purchased at home, but an export permit has not yet been obtained, and the plant is still lying in London. The Government are continuing the construction of the railway line from Batu Arang Station through the Company’s property to Batang Berjuntai; this may facilitate future workings of the colliery at other points in the field. The company’s siding and locomotive were kept in thorough repair throughout the year. An extension of the company’s branch line along the outcrop is under consideration by the board. The colliery is now connected by telephone with Kuala Lumpur, which will prove a great convenience. In common with other mines, labour difficulties were experienced throughout the year, owing to its scarcity, labour being both costly and independent. In this respect an improvement is confidently hoped for after the war. There were no changes during the year in the personnel of Mr. McCall’s staff. Mr. F. J. B. Dykes continued throughout the year to act as the company’s London agent, whilst Messrs. Forster Brown and Rees of Cardiff and London remained the company’s consulting engineers. Until the whole of his services were requisitioned by the British Government in connection with the War Fuel Commission, Professor W. A. Bone, D.Sc., F.R.S. Professor of Chemical Technology, (Fuel), Imperial College of Science and Technology, London, continued his experimental research work into the nature and properties of the coal with regard to its possibilities for low temperature distillation and briquetting. Upon Professor Bone being precluded from further work upon the company’s behalf, Mr. Eric Sinkinson was, upon the Professors’ recommendation, then engaged by the Company to complete the investigations. Owing to the depletion of staffs at Home, this work has been greatly delayed and is not yet finished; but from the experiments made to date it seems certain that the coal will under certain conditions make good briquettes suitable for ocean bunkering. Due to the dissimilarity of Rawang with other coals of the same class, it has, however taken over a year of patient research work and practical experimentation to discovered suitable agglomerants, and a satisfactory commercial method of briquetting. Trials at Leeds on a practical scale are still being carried out. The final installment of arrears on interests amounting to $86,720.62, equivalent to a dividend of five and three quarters per cent upon the total issued capital of the company, was paid on February 5, and there is now no difference between vendor and ordinary shares, both of which are $10 and fully paid and rank equally for all future distributions of profits. The profit for the year subject to directors’ fees, amounts to $243,723.04 to which has been added the balance brought forward from last year’s accounts of $31,972.14. making $275,695.18, out of which has already been paid the arrears of interest dividend due upon the ordinary shares amounting to $86,720.62 leaving available for distribution $188,974.56 which the directors recommend should be dealt with as follows: - In payment of 7 and half per cent upon 150,000 shares $112,500.00, to reserve for bad debts $10,000 balance to be carried forward to the next years’ accounts $66,474.56. Total $188,974.56. The directors deeply regret to have to announce the lamented death during the year of one of their number, the late Dr. Loke Yew, C.M.G., who was an original member of the board. Mr. A. D. Allan resigned from the board upon his retirement from the East. The remaining directors invited Mr. Chew Kam Chuan, one of the trustees of the estate of the late Dr. Loke Yew, to a seat on the board, and this appointment the shareholders will be asked to confirm. The retiring director Mr. Adolf Alois Henggeler, who, being eligible, offers himself for re-election. Messrs. Barker and Co., auditors, retire, and offer themselves for re- appointment. ( Followed by description of A.G.M. as The Straits Echo Mail Edition. 10th October 1917 below)

The Straits Echo Mail Edition. 10th October 1917.and The F.M.S. Chamber of Mines Magazine, No, 5, January 1918 and Malayan Collieries. [Articles] The Straits Times, 10 October 1917, Page 10

Malayan Collieries Development Programme The Annual Meeting. The fourth annual meeting of shareholders in Malayan Collieries, Ltd., was held at the registered offices of the Company 8, 10 Loke Yew Buildings, Kuala Lumpur, on October 2, at 12 noon. Mr. J. A. Russell (Chairman of Directors) presided. Mr. P.P. Spradbery for the secretaries read the notice convening the meeting, and also the minutes of the last meeting, which were confirmed. The annual statement of accounts and balance sheet and the report of the directors and auditors were submitted to the meeting. Chairman’s Speech. The Chairman, in moving their adoption, said: - Gentlemen, - The report and accounts having been in your hands for the specified period, with your permission, I will take them as read. Before moving their adoption, however, I presume you would wish me to make the usual comments upon items in the balance sheet before you. Taking the debit side first, the issued and subscribed capital now stands, you will observe, at $1,500,000, a final call of 75 cents upon the subscriber shares having been made on October last, which makes the shares fully paid, less calls in areas to the amount of $313.81. The calls in arrears are due to two shareholders, both of whom are at the front, and the Directors consider that under these circumstances they are not justified in forfeiting their shares. The item “sundry creditors” consists of wages, Government royalty and freight due by the Company for June account, and has since been paid. The profit I will touch upon when coming to the profit and loss account. Turning now to the credit side, you will see that “mine property” remains the same at $1,003,474,50 whilst “mine development” is decreased from $183.711.97 to $146,782,32. Mine development account was, you will remember, closed as from the end of the 1915-1916 financial year, all work of this nature being now charged against revenue. Furthermore, a sum of $25,000 was written off this account from out of next year’s profits, the sum written off being the approximate amount that had been charged to development after the company had started selling coal. To eliminate from future balance sheets the constant appearance of the item “ surplus on sale of forfeited shares”, this sum also amounting to $11,963.65, has been written off development account. The above two entries make the reduction of $36,963.65 in mine development account as shown in this balance sheet below that of the previous year. To the extension of our workshops and underground brickwork is principally due the increase of $10,244.66 in buildings account, which, after writing off, $4, 629.53 in depreciation, now stands at $58,506; whilst the erection of a fourth bungalow explains the $5,803.37 increase under bungalows, now standing, less $1,689 depreciation, at $12, 302. The Company is at present erecting a small billiard room for the staff. It is practically impossible for our staff ever to get away for long from the mine, and in presenting its employers with a club and billiard table, the Company is not only showing the appreciation of its staffs’ zeal and devotion, but as those who have read any of the recent investigations into the causation of fatigue will readily understand, is consulting in the highest possible manner its own interests. The nature of the additions, amounting to $53,904,79, to plant and machinery, you will have gathered from the mine manager’s report. After writing off a depreciation of $26,570.92 this account now totals $151, 072.68. No comment being necessary on the following five items, we come to stock in hand, consisting of mining stores and requisites. These have been valued by the mine manager on a below cost basis at $34,703.26 The sum of $90,416.91 outstanding on coal sales is principally amounts due for June supplies, and has been since collected. You will see that we have a sum of $175,000 on deposit at the banks plus $1,893 accrued interest. We have $6,130.79 in London to meet payments on new plant ordered, whilst, we have on current account and in hand $5,055.02. With a small item of $824.19 for unclaimed dividends, this gives a total of cash at bank and in hand of $188,903. Turning now to the profit and loss account, mining charges, wages and salaries is the heaviest item, amounting as it does to $252,923.90. Labour rates are not only high but look like going higher. In consideration of increased cost of living, a war bonus of 10 per cent upon their salaries was granted to the European staff at the mine. The Government Royalty of 25 cents per ton of coal sold amounted to the sum of $33,915.97. Depreciation for the year on plant and buildings, the details of which I have already mentioned, aggregates $35,727.44 and has been calculated, I can assure you, on a generously sound scale. Our coal sales for the twelve months yielded a gross return of $760.853.27, but only about half of these sales were made at pit head, the Company paying the rail freight, amounting to $126.97.43, upon the balance. This gives us a real coal sales return of $633,882.84. Coal in stock at the end of the year was only standing at $1,150.97. After adding a small amount for sundry incidental profits, and deducting mining selling and other charges, the Company has made, subject to the payment of Directors’ fees, a net profit for the year of $243,723.04; to which has been added $31,972.14 brought forward from the previous years account, giving a total of $275,695.18, out of which a sum of $86,720.62 has already been paid in interest dividend, leaving $188.974.56 at present available for distribution. Glancing now at the report, you will note that after further prospecting we have taken, during the year, an additional area under lease of 280 acres, making our total leasehold area 2,027 acres. The rest of our concession we still hold under a prospecting license. Vigorous prospecting was carried on throughout the year, but we were handicapped by only having one diamond drill. A further drill was purchased in London, and it was the intention of the Company to keep two drills constantly going on the prospecting area, besides hiring a third set to put down to a deep two-thousand feet bore. Unfortunately, it has not been possible to carry out this idea, for although a priority certificate was obtained from the Munitions Department to purchase the second set, upon applying for an export license from the newly formed War Trade Department, this was refused. There would appear to be certain want of harmony between these two departments, which is regrettable. In the meantime our second diamond drill lies useless at Home. Nor have we been any luckier in regard to a deep boring set. The Government has such a set here in Kuala Lumpur, but only possesses 300 feet of tubing. We have, therefore, been trying to hire a set from one of the oil companies in neighbouring countries; but so far unavailingly. We are now making inquiries with regard to hiring such a set, together with a crew of operators, from America. Besides continuously employing our one diamond drill, we have kept at work during the greater part of the year on the prospecting license area one or two sets of ordinary alluvial boring tools; but these are of little use for coal, and our object in prospecting with them has been more to discover deposits of sand suitable for hydraulic stowage, preferably stanniferous sand able to partly to pay for its own cost, than to locate fresh coal seams. Coal sales for the year totalled 135,663 tons, but the production was somewhat greater than this, the amount burnt by the Company itself not being included in the above figures. Our plant was not only augmented during the year, but we have a considerable quantity of additional plant still on order, partly at Home and partly in America, consisting of boilers, generators, pumps, electric motors, ventilating plant, electric locomotives for underground haulage, air compressors with pneumatic punching and drilling machines for working the coal, cables, rails, tib wheels and axles etc. The wherefore of all this extra machinery I shall presently explain to you. The amount of work entailed at Home in connection with these orders is almost unbelievable. Days of interviews and weeks of interminable correspondence; consultation with manufacturers and our own consulting engineers, negotiations unending, all are required in order to obtain priority certificates of any practical value for the manufacture of our plant. Our trouble is that the class of plant which we ourselves want is also urgently required by the Home Government for the increased British coal output necessitated by the war. Although we are in constant cable and postal communication with our London agent Mr. Dykes, and also with our Consulting Engineers, until I myself went Home at the end of the year I had no idea of the amount of work occasioned by even the simplest orders. I really cannot say what the Company would have done had it not had Mr. Dykes work so energetically and persistently, yet so tactfully, for it at Home. The Company’s thanks are also due to its consulting engineers, Messrs. Forster Brown and Rees, who frequently sent us up to London an experienced colliery engineer from Cardiff to assist us at our interviews with officials of the Munitions Department, and indeed have proved invaluable. We are, moreover, indebted to the Chief Secretary and the Senior Warden of Mines for kind assistance in the matter, the Government considerately addressing the Home authorities on the Company’s behalf. I might say that we received last week a cable form Mr. Dykes as follows: “Priority certificates issued in respect all recent requests and hope obtain delivery about contract time.” I expect that you would rather like to hear some further details with regard to the research and experimental work conducted upon our coal at Home. After over a year’s patient research, Professor Bone gave us an interim report, which was satisfactory as far as it went, but was not complete. Most of the earlier experiments were, I may say, abortive; but the Professor was getting better results at the time he wrote his interim report. At this juncture Professor Bone’s services were appropriated by the Government, and the continuation of the work was entrusted, on his recommendation, to Mr. Eric Sinkinson. Since I left Home, practical briquetting has been carried out, giving most promising results; and now having discovered a successful method of making good briquettes, the question of cost alone remains satisfactorily to be solved. This successful solution to a great extent depends upon the results of the distillation experiments, which latter up to a short time ago did not altogether content us. We obtained good results in the laboratory, but three days trial on a Battersea plant which I myself witnessed at Home proved disappointing. We have now received a cable form Mr. Dykes which I will read out to you: “Sinkinson authorizes me to say briquetting with our pitch in laboratory proved successful no reason doubt similar result on commercial scale percentage pitch obtainable from coal low but would materially assist with foreign binder” If this be so, the question of the cost of briquetting will be materially simplified. In view of Mr. Sinkinson’s knowledge of the difference between previous laboratory results and those on commercial scale, presume that he would not advise that we may expect equally good issues in commercial practice unless he has excellent reason for so believing. You may wonder why we are spending all this time and money on experiments of this nature when, so far from having any spare coal to briquette, we cannot supply much more than about half existing demand for ordinary unbriquetted stuff. But, we do not always anticipate being in this position; we can see a steady local demand for unbriquetted coal up to about 1,000 tons a day; but beyond that figure we cannot safely expect much sale. Now, after the war, not immediately after the war, but perhaps not so very long after it, we are going to encounter very strong competition from Indian and Japanese coals which, if they possess, as compared to Rawang, ash and clinkering disadvantages, are, nevertheless, of a somewhat higher calorific value. In order to meet such competition upon an equal if not better footing, we should like to have an output of 2,000 tons or more a day. By such a daily production we estimate we could get our costs down to a figure that, no matter how low freights fell, would still enable us easily to compete in relative price with the imported fuels. To reach sales of 2,000 tons a day we must get a share of the bunkering trade, and although our coal at the present moment mixed with Japanese is being satisfactorily used for local bunkering, to make it a good bunkering coal we must briquettte it. In considering the cost of briquetteing we have realized that Rawang coal is not exactly identical in nature with any other known coal, so that methods of briquetting that are found suitable for other coals may not necessarily be so for ours. It was, therefore, plain from the first that it might take some years of patient research to achieve a successful issue, and your board thought it better to lose no time in initiating the work which is now arriving at fruition. We may not need at once to install briquetting plant; but we do at once want to know whether or not we need to make provision for the possibility of later on desiring to do so. However, the two most important expenditures we have immediately to face are those of dealing with underground fires and with increasing the rate of extraction. The first is the most serious, for unless we can control these constantly occurring spontaneous ignitions of the seam in the lower workings, we shall never be able greatly to increase our present output, and shall always be confronted with the possibility of serious stoppages and losses. The question of extraction per centage is largely bound up with the control of fires, each fire meaning a considerable loss of coal. Yet even without fires our seam is so thick that the amount of good coal which we have to leave behind in roof supports, etc., is very great. The certain cure for both ills is the replacement of the coal removed by some suitable material flushed by water into the vacancies; in other words, by hydraulic stowage. This is a system that has been common one the Continent for some years, but only since the outbreak of the war has been to any great extent practiced in the British Isles, where the necessity of obtaining for war purposes larger outputs than were formerly considered practicable has recently caused this method to be successfully adapted in several collieries having seam and working conditions approximating to those occurring on our Rawang property. Before deciding upon it, your mine-manager and board have considered other alternatives; but in the end have had to come back to this main idea of hydraulic filling. The principal difficulty lies in obtaining suitable stowage material; search upon the Company’s concession, large as it is, having failed to find a big enough deposit of sand of a nature to suit our purposes. Fortunately, we have obtained the refusal of an area containing over 100 acres of admirable material lying just beyond our boundary. The Company is now actively investigating this deposit, together with the best method of excavating from 800 to 1,200 cubic yards of stowage material daily, washing the same, conveying it three miles to the mine, and pumping it into the workings. To carry out the scheme we shall, incidentally, have to extend our branch line along the outcrop for another one and half miles of double track, equivalent to an extra three miles of single track. Plans for this extension are now being prepared. The installation of an efficient hydraulic stowage plant will not only be dear, but the hydraulic stowage itself will probably add, until we can so increase our output as to nullify it, to the mining cost per ton; but as it will not only, by permitting us to extract a far greater proportion of coal from a given area than we are at present doing, considerably lengthen the life of our mine, but will also enable us effectively to combat fires, of which I may say we have had, big and small, nineteen to date, it patently will be more than worth the initial expense of installation and any temporary rise in working costs. Another immediate and a heavy outlay which we have decided to put in hand is connected with the work of arching various portions of the many roads. This makes for the safety of the mine from break-downs, and though not always done in Home collieries is perhaps usual in the better of them. We further propose to increase our production, lower our working costs, and above all, render ourselves less dependent upon an arbitrary labour force by trying underground electric traction, and compressed air punchers and drills. Electric coal cutters may eventually be installed, but not immediately. Designs for a large automatic screening plant in place of our present grid also being prepared. One of our largest consumptions is in mining timber, we at present using over 200 tons of it a month; and before our mine is worked out we shall probably require every stick of wood that we have upon the concession. We, therefore, to conserve our timber supply and lesson its cost, intend installing a log saw mill and laying a light railway through the forest, making use of nearly everything big and small as it comes along. In order to meet with urgent appeals we daily receive for coal we cannot supply, we are, as a temporary war measure now vigorously extending open cast workings on the North Seam, which you will understand is quite distinct from the Main Seam upon which the underground workings we call our North and South Mines are situated, and this means more, if only locally procurable plant. You will, thus not be surprised when I tell you that we have a programme of immediate expenditure ahead of us of quite half a million dollars. This sum does not include any allowance for remoter expenditure in connection with the sinking of the central shaft, briquetting plant and possibly a distillation plant. These will cost anything from another one- million to one- million- five hundred thousand dollars beyond the half million I have already mentioned. The latter half of the programme we can complete slowly; it is the first part which is urgent; but when the whole is finished you will possess, we feel sure, a coal mine which need not fear comparison for stability efficiency and even output with most or any in Asia. In regard to this expenditure, to that of the first five- hundred- thousand at any rate, it is your Board’s intention to try to meet the same out of profits and you will thus readily believe me when I say that your Directors very seriously considered whether or not they were fully justified in recommending a dividend for the past year of 7 and half per cent; for it must not be forgotten that with the arrears of interest dividend on subscriber shares distributed last February, the Company is really paying a total dividend of 13 and quarter per cent. However, shareholders having waited for so long while the mine has been developed, it was thought that in recommending the rate of dividend to be declared at today’s meeting, perhaps no notice need be taken of February’s distribution and the Board is therefore proposing 7 and a half per cent, even although that rate makes the total distribution for this particular year, considering the programme of development which we are contemplating, rather a high one. We hope to give investors steady and reasonable yearly returns upon their holdings, but I think I ought to take advantage of the opportunity afforded by to-day’s meeting of saying I consider that shareholders should not look for particularly high dividends in the immediate future. Let me explain, at the risk of repetition, more fully the reason for this. When we started, no one apparently believed in coal except the promoters and the small band of enterprising original subscribers, who hardly included a coal consumer amongst them. The Railway Department had tried the coal, but would give the promoters no guarantee that they would use it. Had the promoters been able to obtain such a promise, the history of this Company would have been different. On the strength of such an assurance money could readily have been raised from the general public, the working capital enlarged and a bigger development scheme than one for an output of 500 tons a day planned. With, however, not only no guarantee as to sales, but indifference and skepticism upon the part of consumers the Company was not justified in providing for an output of more than 500 tons a day. In fact I think we were rather brave even to provide for a daily output of as much; and anyhow, quite apart from all that we had not, nor under the circumstances just described could we possibly get, working capital for a larger equipment than a 500 tons a day installation. All this is now changed; prejudice has been overcome, and our ugly duckling is often heard described as being during the war the saving of the country. Our field is proved to be of undoubted value and capable of much greater development. This then is the reason for our ordering all that extra plant of which I have made mention, and for the years of future development work which I have told you are ahead of us; for the corollary that I cannot hold out much hope of high dividends for some time to come. I am the more careful to say all this lest, when now we tell you of our proposed extensive future programme we be accused of want in the beginning of proper foresight and enterprise. You will note, to return to the present, that we are recommending the appropriation of $10,000 to the creation of a bad debts reserve. We have to date sold over a million dollars worth of coal, yet have only incurred a thousand and fifty six dollars worth of bad debts, this consisting of a single item incurred when we were pushing our very first output of coal on to the public. We had at that time to sell to whoever would burn, and the loss ought thus really to be debited against an advertisement account. Our record so far is excellent. Nevertheless, all concerns selling as we do, their produce to the general public should have a bad debts reserve, and this is why we are asking you to approve at this meeting of the formation of such a one. I hope you will also confirm the donation of $500 which we have made to the local Sailors Day Fund, and further authorise us to grant a similar amount to the Our Day Fund. In expressing thanks, I trust that the Railway Construction Department will not mind my venturing to mention how indebted we are to its officers for the kindly courtesy and assistance they have on many occasions been able to render us during the year. To the Mine Department also, we are grateful for valuable aid, consideration and advice. Nor can I conclude without an expression of appreciation of our own mine manager, Mr. McCall and his staff. Their loyalty untiring industry and enthusiasm have been as remarkable as is their animating spirit of mutual co-operation for the success of the enterprise; in fact I consider Mr. McCall to be one of Company’s assets, and think his name really ought to appear along with our other assets on the right hand side of the balance sheet. I now beg formally to move that the report of the directors produced, together with the statement of the Company’s accounts as at June 30, 1917, duly audited, be now received, approved and adopted, which motion I shall ask Mr. Brash to second; but before putting it to the meeting I shall endeavor to answer to the best of my ability any questions which shareholders present may like to put. There being no questions the Hon. Mr. R. P. Brash seconded the Chairman’s motion to adopt the report and accounts, which was carried. The chairman then moved a payment of 7 and half per cent, upon the share capital of the company, the placing of a sum of $10,000 to a reserve for bad debts, and the carrying forward of the balance to next year’s account which was seconded by Mr. A. A. Hengeller and carried. The sum of $5,000 was voted to the directors in remuneration of the services for the past year. Mr. A.A. Hengeller and Mr. C. Kam Chuan were re-elected to seats on the board. Messrs. Barker and Co. were re-elected auditors for the ensuing year at a fee of $1,000, the Chairman in explaining the increase of fee saying that owing to the rapid growth of the clerical and accountancy work in the Kuala Lumpur Office, it would be necessary in future to have six monthly instead of the former annual audits. A vote of thanks was passed to Mr. McCall and his staff on the mine for their services during the past year, Mr. Hengeller further proposing a bonus of one month’s salary be granted to the mine staff as a mark of the Company’s appreciation, which was seconded by Mr. A Grant Mackie and unanimously carried. The meeting concluded with a vote of thanks to the Chairman and the Directors, for which he Chairman on behalf of himself and his co-directors briefly returned thanks. -M.M.

Malayan Collieries Report, Accounts and A.G.M. 1917

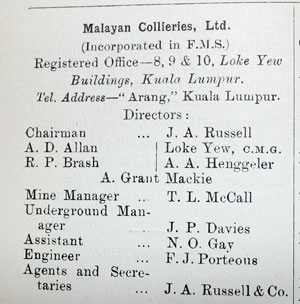

Malayan Collieries, Ltd.

(incorporated in F. M. S.)

Registered Office-8, 9 & 10 Loke Yew Buildings, Kuala Lumpur.

Tel. Address-"Arang" Kuala Lumpur.

Directors:

Chairman J. A. Russell

A. D. Allan Loke Yew, C. M. G.

R. P. Brash A. A. Henggeler

A. Grant Mackie

Mine Manager T. L. McCall

Underground

Manager J. P. Davies

Assistant N. O. Gay

Engineer F. J. Porteous

Agents and

Secretaries J. A. Russell & Co